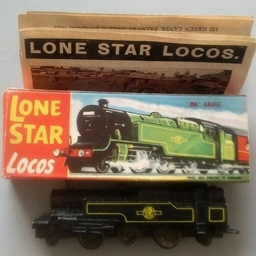

Locomotives were made of two parts, the body and the chassis. The body of diecast in the white metal alloy zamak. The chassis was either 0-6-0, 2-6-2 or 4-6-2, with the driving wheels always the same size and spacing, the middle pair of wheels with no flange. Any non-driving wheels did not have flanges, either.

Locomotive tenders were also made in two parts, the body and the chassis. The chassis was mounted on two pairs of flanged wheels.

The American Transcontinental Diesel had two bogies, each with two pairs of flanged wheels.

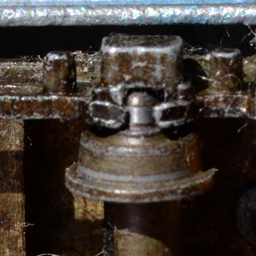

Couplings for the tender engines had the locomotive were made of a riveted tin plate eye and its matching tender would be a down pin. This gave way to a more robust moulded loop and an up pin. The coupling at the back of the tender was always a moulded loop.

Couplings for tank engines and the diesel shunter were usually a loop but sometimes a down turned pin. Early models had the loop made up of a riveted tin plate eye but this gave way to a more robust moulded loop.